® ®

|

Vintage motorcycle chassis |

|

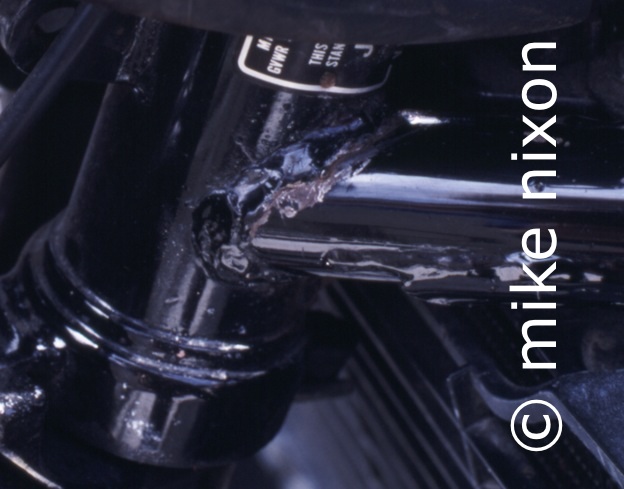

At one time I worked for Honda's U.S. distributor, American Honda, that is, Honda corporate, in Los Angeles (actually the suburb Gardena), California. I have spoken elsewhere about my many years of experience not only in corporate offices but also in Honda dealer service departments, and how after dozens of years of factory training and experience, I really had assimilated a factory perspective. The "party line', if you will. I "drank the Kool Aid", as they say today. In fact, with more than fifty years to date in the powersports industry, I couldn't help but have many vestiges of influence by the various motorcycle manufacturers, and I definitely do. I have however mellowed somewhat and have taken on views here and there that are contrary to all that is holy to the Big Five. One day I was walking across the campus at American Honda and spied some bikes parked outside the R&D department. Ever the curious techie, one turned out to be a new Gold Wing (GL1100) that had a California sidecar attached. If you didn't know, manufacturers frequently test their vehicles, in both standard and non-standard configurations, for a variety of reasons. Well, close examination revealed no other changes, but something odd about the front fender. I finally realized what it was. The fender was actually worn through -- the tire could be seen through it -- in one spot, where apparently the tire had rubbed. Fast-forward a few years. The scene is one of California's then-premier Honda dealers where I am working again as a tech after having left American Honda. A 750 Sabre is on the lot, in for service, and it has a sidecar. And what I saw as well as the reason for the bike being there, was the damaged frame directly behind the steering head.

It may surprise you to learn that steel-tubed motorcycle chassis of the 1970s and 1980s were fairly flexible, apparently made to just the loads necessary, and no more. Look on a vintage GL1100 frame's front downtubes and you will see crimp marks left over from the factory's straightening the frame after welding it. Speaking of frame straightening, two kinds exist on the professional post-manufacturing level. Chassis tuners use the venerable frame table to both create and repair frames. But smaller users use any one of a few portable frame straighteners first popularized by the Swedish company, Samfea, and later manufactured and used by other companies, most notably Computrack. I have used the Samfea Motoliner, and have witnessed firthand that it is ridiculously easy to bend mild steel tube frames. Until 1999, Harley-Davidson used only tapered wheel bearings, going to the more common ball type at that time. Their reason for historically having used tapered bearings seems to have been related to their history of offering sidecars for their bikes. A non-sidecar equipped bike's loads are compatible with ball bearings' radial load capabilities, whereas a sidecar introduces lateral loads that the ball type bearing is not equipped to handle. Tapered bearings on the other had accept both loads equally well.

Here's another picture. This one is a lot more recent. It's a Honda SOHC 750 that my customer crashed hard enough to almost break off both steering stops and and position the right side exhaust system differently than the left on the bike. That's a scissors jack spreading the front frame downtubes so the engine can be slotted back in after a head gasket replacement. Wild huh? The point of all this? Hopefully, it has made you think a little about damage and modifications to your bike. They are not without consequences. They affect future servicing, and they can affect safety. |

© 1996-2015 Mike Nixon